Metals

Reducing production costs while improving quality, productivity and efficiency through optimization of critical resources, are just some of the challenges facing today’s metals industry. Producers must reduce the environmental impact of their operations under stringent regulations. The industry requires oxygen, nitrogen, and argon, for applications from oxygen enrichment for blast furnaces to surface protection and degasification.

Metals Value Chain Steps

STEEL MAKING

Air Liquide supplies industrial oxygen gas, related equipment and services to support steel making processes that utilise Electric Arc Furnaces (EAF's).

Degassing

Air Liquide supplies argon and nitrogen for the ladle metallurgy furnace to stir and refine the melted steel.

Gases

Surface Protection

Our SPAL technology helps producers of steel products to melt cleaner metals to produce castings with fewer defects, enhanced mechanical properties and lower amounts of rejects. The technology uses liquid cryogenics (argon or nitrogen), to reduce interactions between molten metal and atmospheric gases such as oxygen, nitrogen, water vapor and carbon dioxide during air melting operations.

Gases

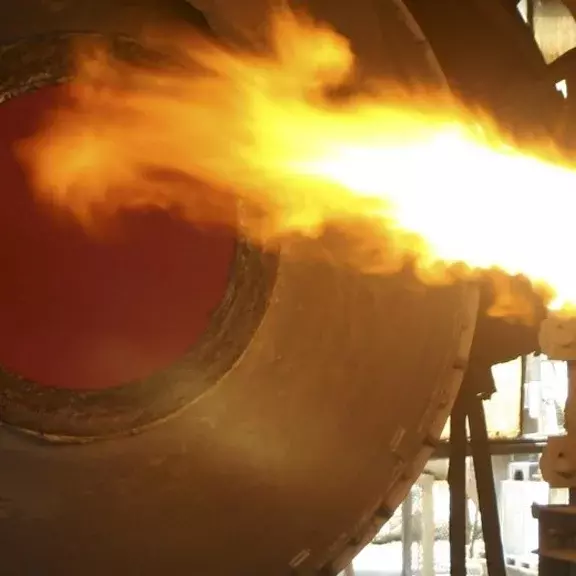

Electric arc furnace (EAF) making

Air Liquide supplies oxy-fuel combustion solutions to maximize productivity of electric arc furnaces (EAF's) at steel mills. Oxygen is supplied for blowing down the metal in an EAF.

Gases

Equipment

Air Liquide’s oxy-combustion expertise includes oxy-fuel burners, oxygen lances, low velocity oxygen injection technologies and related equipment.

Combustion (heating)

Air Liquide’s oxygen, related equipment and services, support combustion applications such as ladle heating and billet/slab reheating.

Gases

Equipment

We supply leading oxy-fuel burners and flue gas for the steel industry.

Services

Air Liquide will conduct a furnace audit (flue gas analysis) as part of our gas package.

Argon oxygen decarburization (AOD)

NON-FERROUS

Air Liquide supplies industrial oxygen gas related to the smelting of non-ferrous metals such as copper, nickel and gold mining.

Oxy-fuel and air oxy-fuel combustion

Air Liquide’s oxy-fuel and air oxy-fuel combustion units are available as rotary or reverberatory furnaces for non-ferrous metals.

Gases

Services

We offer oxy-fuel and air oxy-fuel combustion applications along with related services such as flue gas analysis.

Brands

Developed for the metals industry, Air Liquide’s BOOSTAL™ offers oxygen supply, patented burners, and expert support for the implementation of oxy-combustion technologies for all steps in the manufacturing process.

Inert gas blanketing

Air Liquide’s patented Expanding Gas Air Liquide (EGAL) process, derived from SPAL technology, uses liquid cryogenics (argon or nitrogen), to reduce interactions between molten metal and atmospheric gases such as oxygen, nitrogen, water vapor and carbon dioxide during air melting operations. Our SPAL technology helps producers of non-ferrous products melt cleaner metals to produce castings with fewer defects, enhanced mechanical properties and lower amounts of rejects.

Gases

Primary Smelting

High oxygen levels are used for primary smelting. Reducing the nitrogen content of the off-gas reduces the heat losses while increasing the reaction temperature and reaction rate.

Gases

Mining

Production of non-ferrous metals (Copper, Nickel and Gold) relies on 2 main routes: Pyro-metallurgy (thermal treatment) and hydrometallurgy (chemical treatment through aqueous leaching). The choice of the relevant technology depends on numerous factors and the present share between both routes is very different from one to another metals. Nevertheless, there are signs of significant development for the hydro route compared to the conventional pyro one, which are motivated by the possibility to treat a larger range of ores (especially low grade ores) and even to re-treat dumps, the lower CAPEX, the emergence of new processes/technologies enabling higher productivity and metal recovery.

Customers in gold industry, especially when located “in the middle of nowhere” are asking for cost effective and not sophisticated processes/equipments. They also expect a global solution from their oxygen supplier in terms of injection means and monitoring, in order to optimize their process and their costs. This has been achieved within our ALDOC offer developed for partnerships with engineering companies.

Engineering Groups facilitates the promotion of our ALDOC offer. In addition, such partnerships are also opportunities to be associated to new “attractive” processes.

Gas-Liquid Mass Transfer

- kLa – Volumetric Mass Transfer Coefficient

- kLa = mUGx(P/V)yµZ

- kLa is directly proportional to gas velocity and power to volume ratio

- High kLa means high efficiency

METALLURGICAL PRODUCTS

Air Liquide provides gases and services for reheating furnaces and heat treatment applications to create protective atmospheres for galvanizing and annealing. We serve manufacturers of products such as powder metals, wire, ingots, strip, slab, shot and other metallurgical products.

Extrusion die inerting

Casting

We supply industrial gases for casting applications such as tundish inerting and caster shrouding. Air Liquide’s patented Expanding Gas Air Liquide (EGAL) process uses liquid cryogenics, argon, or nitrogen, to reduce interactions between molten metal and atmospheric gases such as oxygen, water vapor, and carbon dioxide during air melting operations. Our SPAL technology allows foundries to melt a cleaner metal for producing castings with fewer defects, enhanced mechanical properties, and lower rejects.

Gases

Aluminum extrusion

We use aluminum extrusion to reduce oxygen concentration at die to control deposit reaction. In addition to nitrogen supply, we provide atmosphere analysis services for this application.

Gases

Why Choose Us?

-

Reliability

Reliable and reproducible, Air Liquide gas solutions are compliant with the ever-evolving, stringent regulations. -

Environmentally friendly

Environmentally friendly equipment designed with aim to reduce carbon dioxide and nitrogen oxide emissions. -

Industry leader

Air Liquide is a leading global supplier of industrial gases such as oxygen, nitrogen and argon, all essential to the metals industry. -

Expertise

A global network of industry experts is available to support you in developing solutions to meet your unique challenges. Our teams have extensive experience and expertise -

Innovation

Air Liquide’s industry experts are backed by a global R&D network. -

Customizable solutions

Our teams will work with you to identify the most appropriate, cost-effective, gas supply mode based on your purity, flow, volume and safety requirements.